BOW Robotics Services

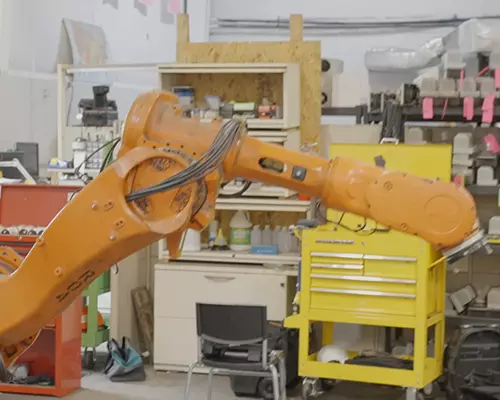

BOW Robotics provides fast, reliable field service and remote troubleshooting for industrial robot systems. Whether your robot is down, underperforming, or showing intermittent faults, our team responds quickly to diagnose issues, restore performance, and minimize downtime. We support a wide range of OEMs and legacy systems, giving you a single, knowledgeable partner you can rely on.

Robot Field Service & Remote Support

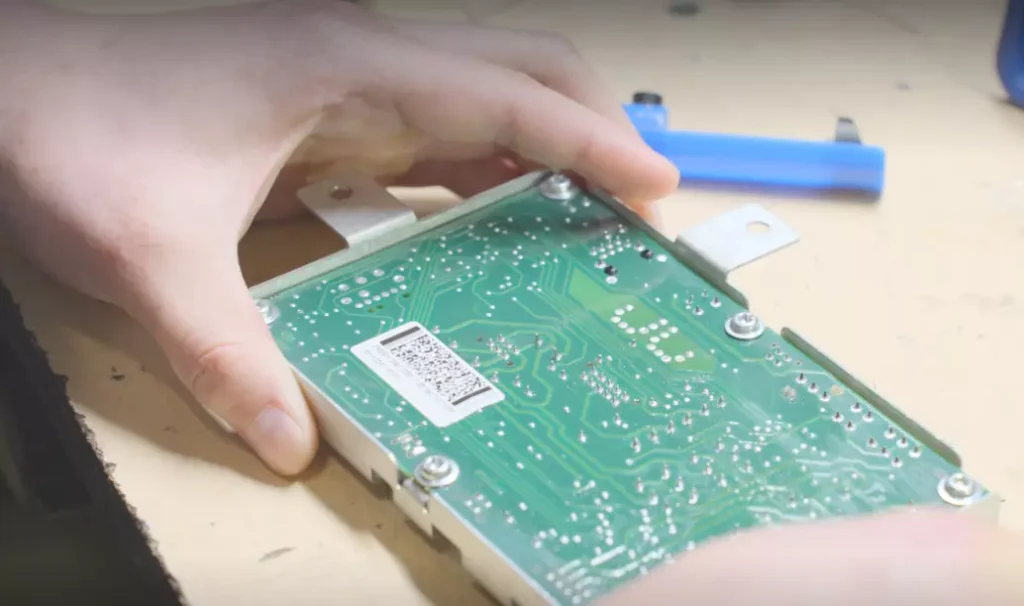

Part Installation and Repair

Robots are complex machines, and replacing a manipulator arm, controller board, wrist assembly, or drive component requires precision and experience. Our trained engineers handle these complex robot repair and part installation services onsite, ensuring parts are installed correctly the first time. We follow proven procedures to protect your investment, reduce repeat failures, and get your line back into production faster.

Robot Programming

Whether you’re updating an existing cell, re-purposing an older robot, or launching a brand-new application, BOW Robotics provides expert robot programming services and support. Our team includes engineers certified across multiple robot brands, with deep experience in RAPID and other OEM languages. We optimize paths, cycle time, and logic to improve efficiency and help your robots meet the demands of your production process.

Preventive Maintenance Services

Robots are high-value assets, and like any automated equipment, they must be maintained to operate safely and reliably. BOW Robotics provides robot preventive maintenance services tailored to your usage, application type, and OEM recommendations. From lubrication and calibration to complete inspections, we help you extend robot lifespan, reduce unplanned downtime, and protect production throughput. Annual or semiannual maintenance packages are available depending on duty cycle.

Full robot refurbishment

Restore aging robots to safe, reliable, production-ready condition with our robot refurbishment services. Our team rebuilds mechanical assemblies, replaces worn components, updates wiring and controls, and performs full calibration to bring older robots back to OEM performance — often at a fraction of the cost of buying new equipment.

Robot Tech Support

Troubleshooting electrical, mechanical, and controls-related issues requires specialized skill and the ability to resolve problems quickly when your line is down. With BOW’s robot technical support and robotics services, our engineers are trained to diagnose root causes, evaluate failures, and provide the most efficient corrective solution. Whether the issue is software, communication, drives, wiring, or system behavior, we deliver clear answers and get your robot running again. Onsite response is available within 24–48 hours depending on location.

Remote sUpport

Get fast troubleshooting without waiting for an onsite visit with remote robot support and troubleshooting services. BOW technicians can diagnose errors, review programs, guide operator resets, and help restore functionality through secure remote access or live video support. A quick call often gets your robot back online and saves hours of downtime.

Robot Part Repair

The Bow Robotics team includes engineers experienced in both electrical and mechanical applications. We provide expert robot part repair services and can rapidly identify root causes to restore components to proper working condition. Our process includes manual circuit and manipulator checks, a minimum of 24 hours of test simulations, and is backed by a 12-month warranty.

Technical Phone Support

If you’re unsure whether your robot issue requires an on-site service engineer or can be resolved by your own plant personnel, our robotics technical phone support can help. Our Director of Technical Services brings over twenty years of troubleshooting experience and works directly with your team by phone. If the issue cannot be resolved within 6–12 hours, a service engineer will be deployed to continue support.

robot cell integration

Adding a new robot cell to your plant? Our robot cell integration services help you evaluate your application, select the right robot and tooling, and recommend the best cell design for the job. From robot selection all the way to production testing, our experienced team will support your robotics integration needs every step of the way.